Guy Reyne is the owner of the atelier Leder Reyne, in Ghent in Belgium, that makes the Puredistance Leather Holders.

When did Leder Reyne first open its doors?

Leder Reyne started around 70 – 80 years ago. I don’t know the exact date the store opened, however, it was just before the Second World War. Leder Reyne has always been a family-owned business, which is currently in its third generation.

What differentiates you from other leather ateliers?

We have always worked with leather and we have 70 – 80 years of expertise in different type of leather. I believe that this is our biggest strength. Furthermore, we have made creative and unique products and customers know that we can deliver and are open to any ideas they have.

What challenges do you face in the leather industry?

The type of demand for leather changed over the years. In the beginning, our main focus was repairing leather for shoes. However, now we create leather cases in any shape & form but also have requests to make other leather products, such as handbags, luggage, shoes and furniture. In this economy it’s important to have these different demands in order to compete with the mass leather production in Asia. If you only focus on making one of type of product, sooner of later it will be produced cheaper on a large scale. Another challenge that we are facing as a small atelier is getting high quality leather since this is hard to buy it in small quantities.

How would you describe the customers of Leder Reyne?

We have all types of customers: big & small companies, customers with repair requests or those with creative design requests, customers from the film industry, fashion industry, luxury industry and customers with background in arts. I believe it’s important to have this variety because it helps us to grow and expand our expertise in leather as well as make sure that we will have projects coming in on a regular base.

How important is personal service for your customers?

For an atelier that makes products by hand, personal service is everything. Our customers appreciate it and like it a lot. The downside of personal service could be that, for us, it is not always possible to make all products. Sometimes we are too small to carry out a customer’s request.

How would you define quality leather?

Quality leather ages beautifully, which means the longer it is used the better it looks. We use calfskin for the Puredistance leather holders and handbags. Calfskin has a tight structure, is light and lasts for a long time. On the other hand, cow skin has more of a loose structure and is often used for furniture and for the interior of cars. Calfskin is more expensive than cow skin.

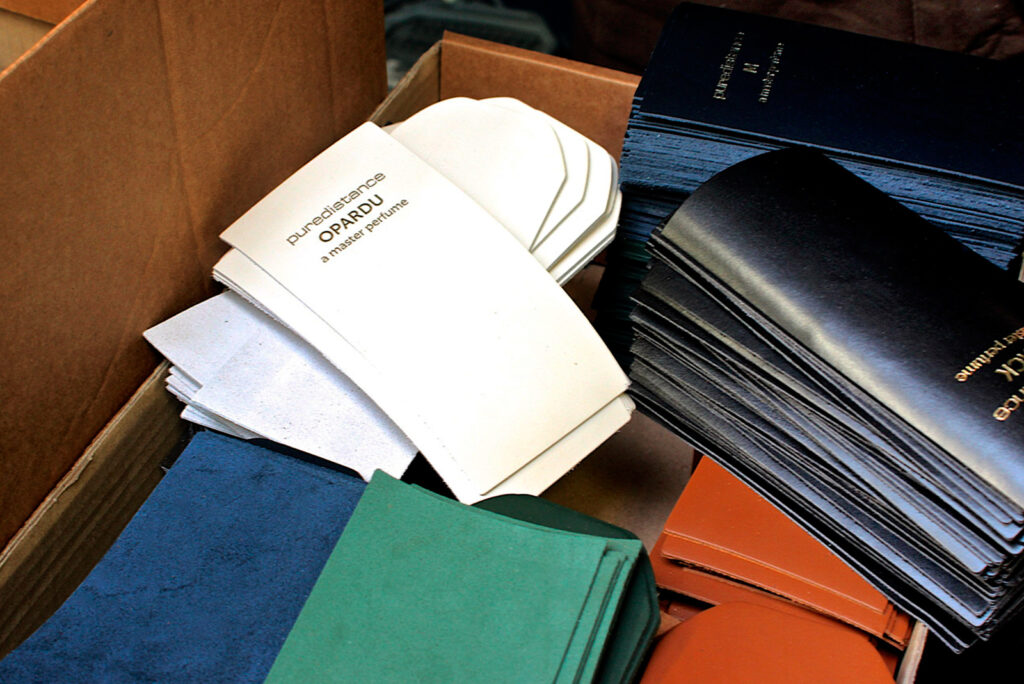

Could you explain a little bit more about the production process of making the Puredistance Leather Holders?

After we receive the right leather for the holders, we stamp out the leather pieces. Each Leather Holder has 2 leather pieces: one for front and for the back. One of the pieces is diluted and we stamp the text of Puredistance on the other piece. Later on, both pieces are stitched together and the edges are painted. It must be said that, even though the leather holder is a small product, there are many steps that need to be taken before delivering the finished product. Making small leather items takes time, which sometimes gets underestimated. It is easier for large companies in China to make them because they can mass produce it and offer it for a cheaper price. However, this doesn’t mean that the quality of the product will always be the same as making it in a small atelier.

What do you think of the fact that nowadays everything is automatized instead of handmade?

A lot of leather production is done in countries such as India and China. However, the costs of producing leather in Asia is increasing. Over the past few years, the salaries slowly increased and there has been a conscious effort to improve the working standards of the employees. Even though these are important working factors, they do influence the costs and make production more expensive. Furthermore, there is currently a trend where ateliers in Europe are getting more design requests and the number of small ateliers opening their doors in Europe is increasing.

Would you consider “handmade” leather products to be something unique?

Considering that a lot of leather products are made by large companies through mass production, “handmade” can be considered as something unique. Customers who buy products that are handmade like this unique factor and they are interested to know who made it. A small atelier can easier provide this transparency since the products are often made by hand and have a personal story. However, it does not mean that customers will immediately buy an expensive leather product. Price and brand awareness are still important purchasing factors. For example, it is hard to sell a luxury handmade handbag for a high price, which does not carry the Hermes or Louis Vuitton brand name.

How do you see the connection between leather and perfume?

Leather skin has similarities with human skin and therefore reacts almost the same to fragrance as our own skin does. Leather has real pores and can absorb fragrance the same way as we do, which makes it a good material to use in combination with perfume. Nonetheless, it is necessary to choose the right type of leather since it already has its own scent, which can influence the scent of the perfume.

What qualities attract you the most in Puredistance?

One of the most important success factors of a company is their employees. What I like most about Puredistance is the Puredistance Team! Everyone that I have spoken to is very friendly and open. Moreover, working with a luxury brand is always nice and gives us the chance to create & experiment with luxury leather products.

What is your favorite Puredistance perfume and why?

At the moment, my favorite perfume is Puredistance BLACK, which is an understated fragrance that doesn’t shout and develops nicely throughout the day. From the female fragrances, I personally like Puredistance OPARDU the most.

To provide the best experience, we use cookies to store and/or access device information. Accepting this will allow us to process data such as browsing behaviour or unique IDs on this site. Denying consent may adversely affect certain features and functions.